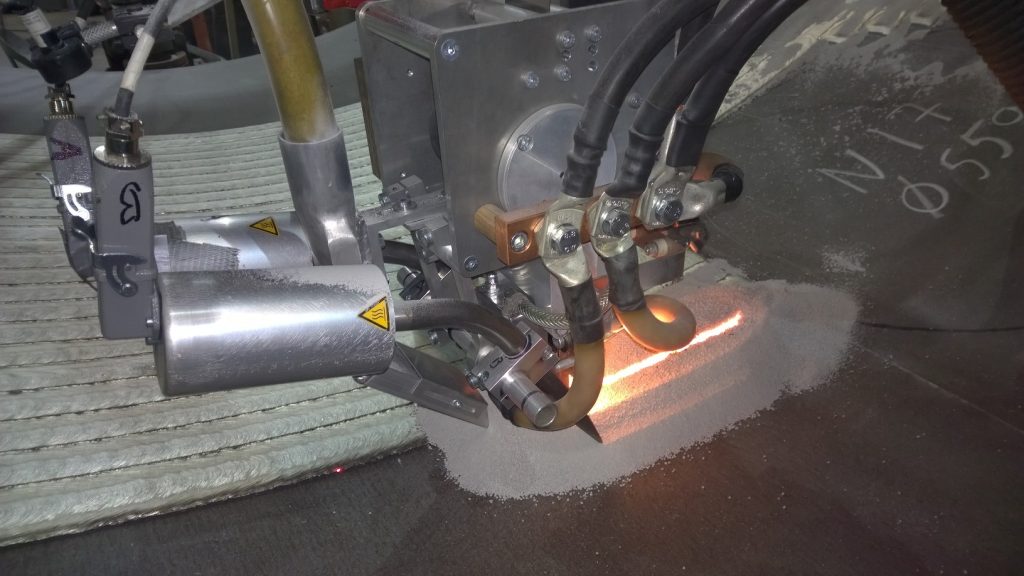

Weld overlay cladding process on the surface of a pressure vessel.

What is weld overlay?

Weld overlay, also known as weld overlay cladding or simply cladding is the process of applying a corrosive resistant or wear resistant material onto the base material.

The base material is usually a basic grade of carbon steel, that is coated with a higher-grade stainless steel, acid proof steel or high-grade nickel alloys.

What are the benefits of weld overlay?

The benefits of weld overlay are increased chemical durability and cost-efficiency, especially in high pressure applications.

With the use of weld overlay it is possible to combine the best qualities of base material (pressure caring body) and coating material. Weld overlay provides a surface protection whereas the base material provides strength requirements to meet codes and standards.

How we use weld overlay at West Welding?

West Welding has a history of doing weld overlay with various materials, including different heat resistant stainless steel, acid proof steels and nickel alloys like Inconel 625.

Usually, we have used weld overlay on insides of entire pressure vessels, including nozzles. For pressure vessels, the base materials we use are for example P355NL2, P335GH, 16Mo3 and 10CrMo9-10.

Picture: It is possible to apply weld overlay on even large pressure vessel.

Want to hear more about the benefits of weld overlay to your company?

Contact our sales personnel to discuss about the options.

You can also follow us on LinkedIn or subscribe to our newsletter for more content.